Quality comes from creation, the strength lied in brilliance.

100% inspection staff posts after passing through the evaluation, development and implementation of the annual training plan, so that each person has a good awareness of quality management and skilled according to the actual needs of staff.

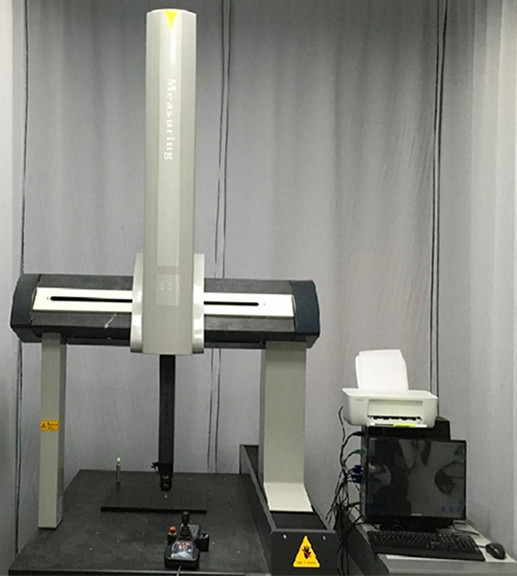

100% of each batch of access to materials strict testing with the quality management system standard . Wherein the detection device has three coordinates tester, profiler, 2.5 yuan, height, Vickers hardness tester, and other detection equipment throughout the entire production sectors; 3D coordinate tester and various test software greatly improve the quality of guarantee capacity. According to product regulation requirements were developed a complete inspection process control plan for each channel sampling program for the inspection process and detailed provisions; in particular control test of the first pieces of various types are planned in accordance with the requirements of the first pieces of 100% inspection, eliminate the bad batch manufacturing process; at the same time during the manufacturing process step by SPC to analyze the use of various types of control charts to analyze the manufacturing process to ensure our Cpk≥1.33, Ppk≥1.67.

Our Goal—100% Customer Satisfaction

Quality testing equipment